Please widen your main browser window

if the right hand scroll bar of this

inner browse window isn't showing.

Please read the copyleft link at the bottom of this page for further details, the rights given by this license are very generous. Not at all like most licenses you are probably familiar with.

This scrollable inner browse window is nestled between two schematics, which it often refers to. The upper schematic is a series wired ohm meter, the one below is a parallel wired ohm meter. Each has characteristics unique to itself. The material presented here, while not particularly germane to converting a DMM to a DPM, it nonetheless does provide some theoretical background to how ohm meters work. Volt meters are by contrast relatively straight forward, from a theoretical point of view, hence I give no special treatment in this section.

The above type of resistance measuring circuit is usually employed with a Digital Meter, but that was not always so, in the early days D'Arsonval meter movements were used. Mostly because digital requires lots of active components, such as vacuum tubes, which are expensive, unlike transistors that can be fabricated by the thousands on a single silicon die, tubes are large, hot, power hungry, and tend to use high voltages, and high impedances, which is bad for frequency response, making them slow in the digital world.

Fast-forward to the technical vastness of the future, we have little epoxy blobs on a circuit board that contain a mind bogglingly complicated circuit that consumes a billionth of the electrical power of their vacuum tube counterparts, that is scarcely larger than a pencil eraser, wow isn't it neat living in the future?

Sorry I tend to get off topic once in a while...

In this circuit the meter, and the resistor under test are in parallel, if you consider the voltage follower Op-Amp to be part of a very high impedance volt meter head. Unlike the previous circuit instead of a voltage source, driving a series circuit, the transistor is biased in such a way that it forms a constant current power source that's in parallel with the meter, and resistor under test.

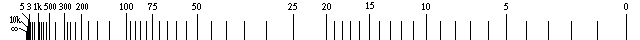

OK. So the two circuits are different, even drastically different, but why? Well have you ever seen the Ohm scale of the serial version of the circuit, Zero ohms, is at the right most end of the dial, what is often called FS or Full Scale, then working leftward this scale increases in value, the opposite of what you'd expect. The formula for this nonlinear scale printed on the dial of a meter used with the series wired circuit, I list below. In short it's an arithmetic reciprocal function.

1

D = -----------

R

--- + 1

S

Where

D = the fraction of full scale dial

deflection the needle points to

R = Resistance of resistor under test.

S = Scale factor: This number is the

range setting (Rx1, Rx10, Rx100 etc.)

But also takes into account the printed

ohmic numbers on the dial face, see the

note below for the exact method to get

the value of this term.

The above formula requires a term

labeled S called Scale. The

Scale Factor stretches the linearity, or lack thereof to match

the the physical multi-meter. There are two ways to accomplish this

depending on whither the meter you are about to scale already has an ohms

scale printed on the dial, and you just want to repaint the dial or you

are building one up from scratch.The above type of resistance measuring circuit is usually employed with a D'Arsonval meter movement. Everything, the resistor under test the battery a voltage source, and the electromechanical meter, are all wired in series.

First the repaint case:

People redecorate dials all of the time. Most meter dials are held in place by two machine thread screws, and the dial itself is symmetrical. So if you unscrew the two screws, remove, flip the dial end for end, and re-attach it replacing the screws, you now have a blank, bare metal dial that you can paint anyway you want. However before you flip the dial you need to get the center point scale factor from the old dial markings. Locate a linear voltage range, use DC, because the AC range isn't quite linear due to the diode required to measure AC. Next locate the halfway point, 50 percent of full scale. Now either imagine needle pointing to this midscale position, and try to see what resistance this same needle will intersect with. That's your Scale Factor. For simplicity the range selector switch is assumed to be at Rx1 to make the math simple.

Second the built from scratch case:

You've just wired up a series ohm meter and need to scale it for the first time. Choose a high range, say for instance Rx1000 assuming you designed it to have an Rx1000 position on the range selector switch. A high range will use less battery current, and lower lead current which is less strenuous on the potentiometer you will use when it comes to the obtaining the midscale resistance. now short the ohm meter leads. Next I would say set the zero ohms adjust to full scale. The trouble is you probably have no dial markings to go by. So where exactly is full-scale? Perhaps here I should mention that many a D'Arsonval meter movement have a full-scale terminal voltage of a quarter volt, or 250 Mv. So now, if you connect a DMM directly to the D'Arsonval meter-head terminals, and set the electro-mechanical instrument's zero-ohms adjusting potentiometer to get a reading of 250 Mv, on the DMM and check that the electro-mechanical instrument's D'Arsonval meter head is comfortably at full-scale, not pinned against the right hand limit peg, nor substantially left of that point either. A good rule of thumb is that full-scale should be five percent lower than than the point the needle touches the limit peg. If your electro-mechanical D'Arsonval meter head is not at full-scale when 250 Mv is applied, you have an unusual meter-head, use this setup to determine what voltage is full-scale, as read on the DMM, and write that down. Three other things

1. The protective plastic window that covers the dial, and needle, can collect a static electrical charge, and the field can pull the needle away from its true position. Use an antistatic spray on the inside surface of this window, to reduce the likelihood of this affecting your reading.

2. Engineers don't standardize things like meter-head FS (Full-Scale) voltage at odd values, they like nice round numbers, like one quarter volt, or 200 Mv you'll never see an FS voltage of 0.78437 volts for instance, unless something's wrong with the meter.

3. Don't rule out the possibility that something is wrong with the meter, I once inadvertently seriously reduced the sensitivity of a meter-head I was working on.

I digress, I once had a meter that had many tiny iron filings down in the core of the meter, where the moving coil was critically gapped between the magnetic pole pieces. There are two very delicate hairsprings, that set the zero position, and also carry current to the coil. A couple of these tiny metal shavings, even half a dozen, you might pull out with a small magnetizable wire, but hundreds of them? You'll damage the poor thing long before you rid it of them. Then I noticed that the magnet was held inplace with a brass bolt, and nut. I removed the bolt, slid the magnet out, and quickly slapped, an iron keeper on the magnet, to keep it from unnecessarily loosing magnetic strength. Next while tapping on the frame of the meter-movement, and gently blowing through the middle of the assemblies core I managed to free it of all the iron filings. Then I slid the magnet off the iron keeper, and back into the meter assembly, and the mechanism glided freely throughout the entire range when I would gently blow on the needle against the dial. I then put the multi-meter back together, and all the voltage and current ranges were reading about 30% lower than they should. Not only that, with a fresh battery in the unit, I couldn't zero the ohms adjust! I had desensitized the meter by removing the magnet from its inherent natural keeper. I later fixed it by gluing in an additional magnet, but I learned a valuable lesson in the process. now I progress.

OK the DMM reading of the full-scale deflected electro-mechanical meter you wrote down, needs to be divided by two, write that one down below the full-scale reading you took earlier. Next get out a suitable potentiometer, and reading the DMM, dial it up to the point where the DMM reads the full-scale voltage divided by two, that you wrote down. You should also observe the electro-mechanical meter, it should be deflected to the mid-scale dial position, with or without the dial actually screwed into the electro-mechanical meter movement. Now disconnect the potentiometer from the ohm meter you are building, taking care not to accidentally bump the shaft, changing its resistance in the process. Now disconnect the DMM, from the terminals of your D'Arsonval meter movement. Now use the DMM to measure the potentiometer used earlier. The reading you get is the Scale Factor for the Rx1000 range, assuming the range selector position you used was Rx1000. If that was the range you used, you can convert to Rx1 by dividing the Scale Factor you obtained by 1000 in this case. Note: had you used Rx100 in the first step involving the potentiometer, you would divide by 100 to get the Rx1 Scale Factor, and so it goes for other ranges, simply multiply accordingly.

Using the formula I gave you above, if you write a program for a programmable calculator, or a computer language, this sort of thing is where even BASIC shines, it's quick-n-dirty, but it gets the job done. What you do, is to write a program that iterates through a series of resistances using the Scale Factor you just obtained with the formula I gave you, giving you D and R Deflection/Resistance pairs, with which to scale a dial. If you start up a paint program, such as Gimp, or xpaint, starting with the first D/R pair, you use the deflection value, multiplied by some magnification factor, chosen such that the whole meter scale will be on the xpaint canvas at the pixel count called out by the deflection value, times the magnification, you place a tic mark, and use the text feature to write down the resistance associated with that deflection, then press the calculator button to get the next D/R pair, and repeat the process until done, or at least until the deflection steps become so small that they exceed even this high resolution, note you can make the dial 1000 pixels wide. Remember the reciprocal function reaches to infinity, a physical location on the dial! Obviously from time to time you have to change the size of the iterator due to the nonlinear nature of the reciprocal function. Once you've got a dial laid out on your computer, you can reduce the image to print at your printers maximum resolution, an adhesive backed paper dial overlay.

The parallel wired circuit, that uses a constant current power source, and a very high impedance volt meter, high enough to make the meter's loading effect negligible, used to measure the resistance of resistor under test requires a linear ohm scale be printed on the dial of the meter. If the meter in question is digital, having a circuit that requires a linear scale is a very big plus! It means no conversion is necessary, and makes the whole circuit a lot more simple. Why is this? If you place a constant current across a resistor under test lets say for example one milliampere, then for every thousand ohms, of resistance your resistor under test will drop exactly one volt, so a reading of five volts means that the resistor under test is 5.0 K ohms. So it's not surprising that the ohm measuring section of modern DMMs use the parallel circuit, rather than a series one. I tell you all of this because you are going to study the range selector switch to figure out how to convert a multi-meter into a single purpose unit suitable for panel mounting in some instrument you are building. Knowing how they work can be a great help.