Alert!

This lesson's lab experiment uses dangerous voltages, and currents.

If performed incorrectly your likely hood of survival is rather low.

Performed correctly, using the precautions I describe here in, raises your

likelihood of survival to a level comparable with walking across the street,

on a green walk light, or driving down the freeway at a safe and prudent speed.

People still get squashed by a bus walking across the street, while doing

everything in their power to observe well known safety rules, and while

employing common sense. Safety rules do not guarantee survival, but they help

tremendously. Furthermore upon hearing of news that someone was squashed by

a bus while walking across the street, seldom deters onlookers from walking

across the street an hour later, they simply look death straight in the eye,

and stare him down, resolving to do everything in their power to avoid getting

squashed, but not to the exclusion of walking across the street, they merely

do so carefully. The danger this experiment exposes people who carry it

out to, will probably kill one person in 10 billion, even though they

meticulously follow my instructions. If these odds are too great for you, my

advice is to become a shutin, never venturing out into the dangerous world

around you, and stop taking this course. Life is a "Calculated Risk" there are

no guarantees, not even that you will survive. I offer no guarantees that my

experiments are safe, indeed, I am telling you that they are not safe.

That said I do my best to outline reasonable precautions that will greatly

increase safety, but the risk is yours, I cannot be responsible for the myriad

of mistakes people will make. If I tried to plan for every conceivable

eventuality, one, this web site would never be completed, and two, every

contingency planned for, potentially introduces

even more risk so such

planning is doomed to failure anyway. This experiment, as do all of my

experiments, teaches something important, this one demonstrates in a very

enlightening, and hands on way, the difference between reactance, and

resistance. It leaves a lasting impression of just how different they really

are, but to do this requires several watts of electrical power, at voltages,

that are high enough to be dangerous. Using lower voltages would make the

experiment unreliable as obtaining the specialized components could not be

relied upon in the kind of setting this Web based course is designed to be

used in, where you the student are required to locate all of your own

components. And let's not forget, someday sooner or later, you will have to

work with dangerous voltages, better you become familiar with techniques

that can offer a reasonable margin of safety now, in a somewhat controlled

setting, than later in a setting where a snap decision proves fatal.

If you feel uncertain about any of the safety information I provide, talk to

someone who is experienced in working with electricity to get clarification

on the points you are fuzzy on. Make sure you understand the "whys" of the

dos, and don'ts before you attempt the experiment.

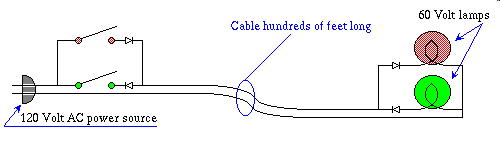

Under no circumstances perform this experiment without listening to all the

audio, critical safety information is contained in the MP3 audio that is

part of this page, among other things I discuss the three levels of

separation, some people call "Fail Safe" that must be observed at all times

when working with dangerous voltages. To be electrocuted all three have to

breakdown, this is what gives you relative safety. I go way overboard on this

but I assume you are a novice, and as such, since I cannot be there to watch

you, the best I can offer are a set of rules, silly as they may seem, they

are not silly if they save your life. Sooner or later you will have an

incident when one of them break down, the other two, because they were in

place, are what is saving your life, later when you have time to reflect

you will understand why they are not so silly after all.

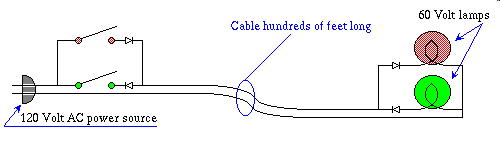

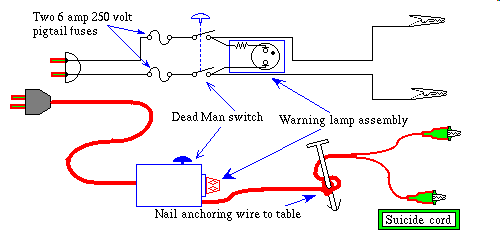

In the audio I discuss having a onlooker in the room to break the circuit,

and render assistance should the need arise. Make sure that this person knows

that they are to pull the plug of the extension cord from the wall socket,

not the table leg end, in the event of a mishap, and that they are not to

touch you, until the flow of current has in this prescribed way been stopped!

If they were to touch you... and this is what an untrained person is likely

to do, because they instinctively will attempt to pull the victim away from

the live wire. Doing this will likely get them electrocuted as well! Make

sure they know how to contact emergency medical assistance by phone, and if

they are trained in CPR, Cardio Pulmonary Recessitation, so much the better,

but call before attempting recessitation, and when they place you on hold,

turn on the speaker phone, and attend to the job of recessitation.

Click the "Audio discussion" link now, then

read on while it's downloading. When it

arrives, come back here, to start, and as I

progress through the audio discussion, I'll

instruct you to proceed from one pictorial

to the next, like a slide presentation

014_Setting_up.mp3 Audio lecture

on setting up a high voltage work area 8.79 meg

Experiments using real electricity

Your Notes:

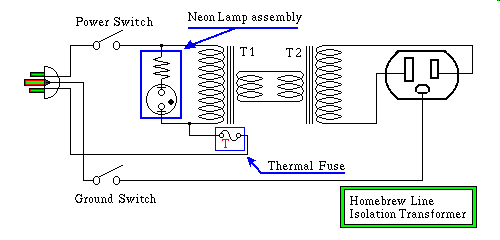

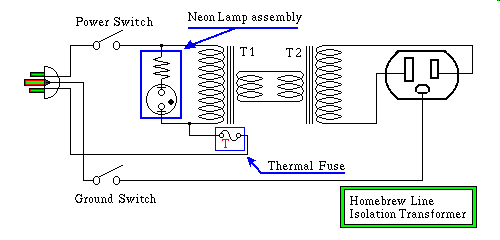

This lesson segment is nearly all lab, and when you complete this lab you

will have some additional useful test equipment. The first item, the

Home Brew Isolation Transformer, is to be built only if you

have on hand, two large, eg. in the range of 300 VA, eg. 300 watt, or above

nearly identical 120 volt primary to some other voltage secondary

transformers. If you don't already have a couple of these sitting around

unless you happen onto a couple of them, real real cheap, you are probably

better off buying an isolation transformer. Mouser has one for $62.16 that

delivers 2.1 amperes, and considering the effort you'll put into building

one, you better not have paid very much for the two transformers that makeup

this project. What is meant here by nearly identical, is one, the VA ratings

are within a two to one ratio, one to one is ofcourse best; and two the

secondary voltages of these transformers is within a ratio of 1.0:1.1 that

means as an example, that if one of the transformers secondaries was 24 volts

at 15 amps, and the other transformer was 28 volts at 25 amps the pair would

not be suitable for this use, because 28 divided by 24 is 1.1667 and that is

just too high, even though the power levels are fine. 24 times 15 is 360 watts

which is plenty of power to build a 200 watt Isolation Transformer.

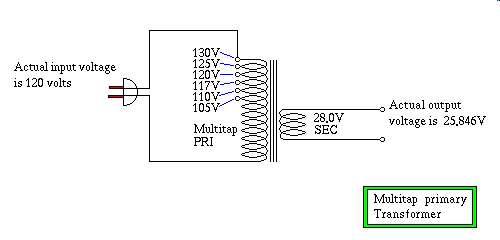

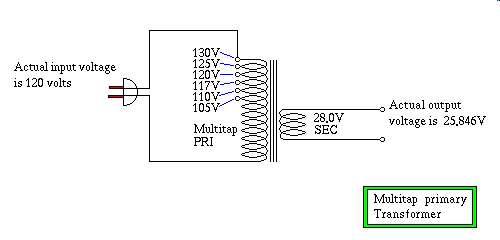

However upon looking at the primaries of the larger one, you happen to notice

that it's primary has an extra set of terminals for a tapped primary input

voltage that will allow an input of 130 volts. See the second picture in this

page, titled "Multi-tap Primary Transformer" Upon running the ratio numbers

you would discover that deliberately setting the wrong tap, making the

transformer a 130 volt primary, and then running it on 120 volts, a lower

voltage than it was designed for won't hurt anything, and it changes it's

output voltage from 28 volts to 25.846 volts. Now the voltage ratio of the

two transformers is 25.846 divided by the other transformer's secondary of

24 volts gives a ratio of 1.077 to 1 which makes it a perfect choice. It will

run the small transformer a little bit hard, but losses in the total system

will be somewhat canceled, by the fact that you are driving it a little harder

than the absolutely correct voltage.

A safety issue here to consider is that if the secondaries are a high voltage,

like say 700 volts, you probably shouldn't use these transformers as a

Home Brew Isolation Transformer because if the insulation

should break down, or moisture were to condense in just the right places

the isolated secondary could be giving off a very high voltage with respect

to earth ground. I mention this here, primarily because one might be tempted

to use a pair of transformers culled from two old worn out Microwave Ovens.

This is tempting because they handle about a thousand watts, and you could

easily build a five hundred watt isolation transformer from two such

transformers. My feeling is that it isn't worth the risk, I wouldn't use

a transformer for the purpose of building a

Home Brew Isolation Transformer

that stepped up more than double the line voltage as a rule of thumb.

Using step down transformers for this purpose is always safer.

I have found sources some of the parts for this and other experiments. I am

not necessarily recommending them, just mentioning them as a possibility, you

should scout out your own home stomping ground for sources of these materials

and don't overlook Flea Markets, Ham Fests, and Army Surplus stores.

Switches suitable for the Dead Man switch

-------------------------------------------

Vendor stock nbr rating price

Radio Shack 900-8572 6 amp/250 volt 3.69

Mouser 103-4025 6 amp/125 volt 3.18

Thermal fuse suitable for Isolation Xfmr

-------------------------------------------

Vendor stock nbr rating price

Radio Shack RSU 11308467 189 deg F 1.29

MPJA 5357-TF 91 deg C 1.00

Neon indictor lamp assy

-------------------------------------------

Vendor stock nbr rating price

Mouser 36HN010 110 volt 1.82

About the Mouser 103-4025 switch, neither the Mouser, nor the Radio Shack

version, is a true push button, rather both of these are

"Momentary Toggle" switches, that is they have a spring action that

upon release return them to the previous position, the Mouser version offers

a small safety feature in that it's lever is made of insulated plastic.

As an alternative you could mount two SPST Pushbutton switches, one on each

side of the box, arranged so that your thumb and forefinger can press both

buttons simultaneously, in a squeezing motion.

Oops I just threw in a another term you might not be familiar with, what is

SPST, it stands for Single Pole Single Throw. Ya' fine you say now that does

that mean, Ok Ok I'll get there. You will see switches designated by

acronyms like SPST, where sometimes the "S" is replaced with "D" meaning

Double. Think back to the days of early electrical experimenters, most famous

among them being Doctor Frankenstein, or maybe Dr. Tesla comes to mind, not

that he was ever on a par with the other :-) In their labs when Hollywood

needed to Juice things up there was the closure of this really nasty,

menacing looking Knife Switch, that always went sparky sparky when it was

operated. It is that Knife Switch that will serve as a good memory gimmick

to help you keep straight what things like SPST means. The Poles, are the

Knife blades, that swing from one throw to the other, in a real Knife

Switch, the kind Hollywood uses for effect they look like Poles pivoting

on the center contact. The action of Throwing the Switch, is that of moving

the Pole to a different Throw. Therefore a Double Pole switch is one that

has an insulator bar with handle, that links both poles together so that

the hand that throws the switch causes two circuits to change simultaneously.

A Double Throw switch is one which has contacts on both of the positions

that the switch can be toggled to. As an example the four wire pushbutton

switch I show as the Deadman Switch is a DPST switch, as an exercise to

insure you really grok this stuff, a DPDT has six wires, a SPST is a two

wire device, a the SPDT is a three wire switch, a SP6T is probably a rotary

switch, the kind with a knob, and six positions, and it has seven wires.

Similarly a 4P12T switch has 12 positions and 52 terminals for wires, think

old fashioned mechanical TV Tuner, my were those things complicated!

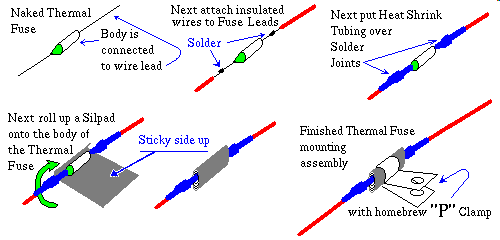

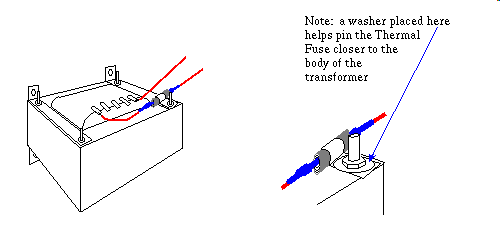

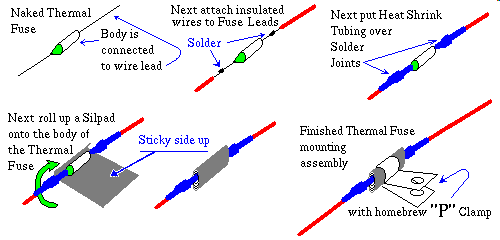

The MPJA (Marlin P Jones and Associates) 5357-TF thermal fuse has a screw

mounting ear to fasten it down the thing, in this case the transformer,

that is to be protected from overheating. The radio shack thermal fuse

poses an interesting problem, to pick up temperature it must be provided with

a thermal connection to the thing that is to be protected, on the other hand

it's body is electrically connected to the AC power line! So you need a very

special electrical insulator. While it must be conductive of heat, it must

not ever become conductive of electricity, this is especially vexing because

many such thermally conductive, electrically insulative materials, melt at

high temperatures. Melting would allow the body of the thermal fuse to make

contact with the body of the transformer, causing it to carry the dangerous

AC line voltage. There are special heat conductive Epoxy compounds designed

to address this need, and there is a product called Silpad which is an

adhesive backed sheet material, looks rather like adhesive tape, that is

impregnated with thermal conductive Silicon. The Silpad samples I have seen

are about as thick as Duct Tape, and are pre cut into various shapes, placed

onto Release Paper, like Postal Stamps. If you were to cut a strip out of

a coffee can a half inch wide, and 1.5 inches long, you could drill 3/16"

holes in the ends, and bend it into a "P" shape clamp around the electrically

hot thermal fuse, that has been prewrapped with Silpad, and the wire ends

should be covered with shrink tubing after soldering insulated wires to the

ends of the thermal fuse.

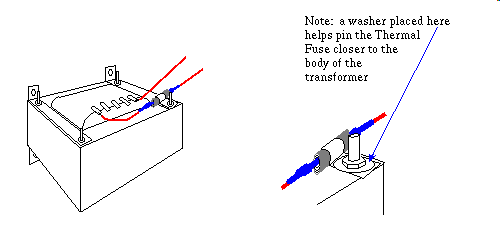

Assembly of Isolation transformer

The material you would choose for an enclosure for your homebrew isolation

transformer should be plywood, Masonite, or plastic. Do not use metal, the

whole reason for building an isolation transformer is to block a direct

path of current from the powerline to you. Each of the two transformers

are capable of providing a level of isolation, unless... If you mount them in

a metal enclosure, the enclosure itself can provide an unfortuitous path

bypassing part, or all of the isolation. On the other hand, wood is a fire

hazard, it's a little like having to choose between the lesser of two evils.

That's why I spend so much time on thermal fusing the power input transformer.

Transformers are particularly problematic from the standpoint of fire safety.

If a short circuit between any two adjacent windings inside the transformer's

coil occurs, what you have is the mighty output of the entire transformer,

its combined turns ratio, of its primary winding stacked against that single

shorted turn. The shorted turn can be anywhere in the transformer, primary

or secondary, the end result is the same. The entire output is diverted into

this lone shorted turn. Such a single turn produces a very low voltage,

usually a small fraction of a volt, at hundreds of amperes. The result is

that it gets incredibly hot, and melts away all its insulation, and

the insulation of nearby as yet undamaged windings. They too ultimately

short, and now contribute to further destruction of even more nearby windings.

This shorting of adjacent windings is not unlike a cancer of the

transformer, and it spreads until the primary draws so much current that

a wire burns open, or a fuse, or, circuit breaker blows. What you may not

understand is that a transformer fused with a current limiting fuse, can

because of this process, long before the current limit of the fuse is reached,

create so much heat that the transformer will glow yellow hot! Such

a transformer mounted to wood, can start a fire. That is why I spend so much

time giving information of proper thermal fusing, a thermal fuse doesn't blow

because the current has been exceeded, it blows, or opens because its

rated temperature has been exceeded, which is precisely the proper way to fuse

a transformer, then if you want to put in additional fusing, in series with

the thermal fuse that is up to you, but the thermal fuse is critical.

The base of the Isolation transformer wooden enclosure should be made of a

thick plywood baseplate, say one inch thick. The sides, front, and rear, can

be thin quarter inch plywood, or eighth inch Tempered Masonite, and Masonite

is easy to work with, and looks good unpainted, however the top should be

made of five eighth's inch plywood because this allows you a solid cross

sectional area to sink your wood screws into for fastening the sides, front,

and rear, panels. Finally place corner molding pieces in all four corners to

provide solid pine to allow something for wood screws to sink their teeth

into for fastening of the sides to each other. The base of the enclosure

is ofcourse the surface that you mount down all of the heavy components to,

such as, and especially the transformers. None of the screws should be long

enough to protrude through the bottom of the cabinet, not only is this a

potential electrical safety issue, but wood screws have sharp points, and

sliding a heavy wooden cabinet with a sharp screw point sticking out of the

bottom, will marr the surface of your nice Formica top, in a way that

finished plywood by itself will not. The outlet receptacle should be

mounted to one of the sides, being they are smallest Masonite plates, and the

plate that holds the electrical outlet should have enough screws to hold it

securely while things are plugged into, and unplugged from the electrical

outlet that it is supporting. For screws consider using hardened steel drywall

screws, these have a very aggressive thread pitch, and are kind to wood, in

that they seldom cause it to split. If you are of a mind to use glue, I

recommend building this cabinet in two pieces that fit together, one piece

has the bottom, and the end with the outlet mounted to it, and the other is

the the top, and the other walls, should repair ever be necessary, you'll be

glad you made it that way. As for the wire that connects the two low voltage

windings to each other, this needs to be very heavy wire, the lower the

voltage they are, generally speaking the heavier the wire, a good rule of

thumb is use wire that is atleast three gauge sizes lower, than the wire

exiting the transformer. Note the lower the gauge size the larger the wire.

By using wire three gauge sizes lower, you nearly double the cross sectional

area of the current carrying copper wire.

Construction Notes:

Many of the construction techniques I show here are useful everywhere

electronics projects are built by hand, therefore you should create a separate

file in your "Electronic Notes" directory specifically for construction

techniques, keep in mind my warning about

avoiding Proprietary Formats

from the end of lesson 010. It may sound a bit preachy, but the advice is

essential to any creative endeavor, and this course teaches creativity,

disguised as electronics. Maybe that is too strongly worded, you may have

heard that creativity cannot be taught. I for one believe this to be true,

but I also believe that genuinely creative people are easily duped into

pursuing a life in which, their creative potential is never realized.

Oh and by the way if you haven't already done so take a gander at

my tool abuse page

it shows how to think like a tool maker, as opposed to a tool user.

For those of you running some variant of Unix, in the "X" window system,

it can be handy to open multiple "Desktops" simultaneously, one catering to

applications and files dealing with hardware notes, purchasing of, or

acquiring free samples of parts, a drawing package for maps, and other

doodles, and so forth, and another desktop for the study of electronics

itself, and yet another for the browser, and its ancillary windows, this

gives a nice uncluttered appearance, and beneath all of this are a dozen

or so virtual terminals for those nice crisp Emacs screens that GUIs will

never touch, oops way off the track, back to the project

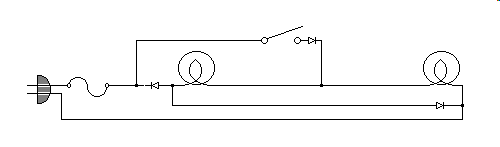

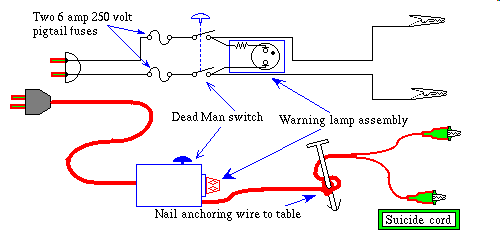

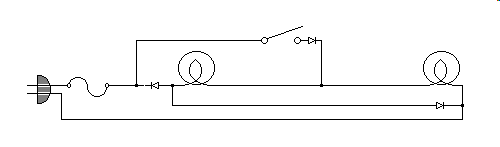

Assembly of Suicide Cord

After building the Suicide Cord, you need to test it to be sure it is reliably

safe to use. First a visual inspection before the box is closed up. You are

looking for anything that could create an unplanned path of current.

Multistrand wire poses a danger if a stray thin strand of wire accidentally

makes contact with something that could carry current to you. Even if not

actually touching something now, after the box is closed the wires may move,

and if it were to make contact with something made of metal, such as the body

of the switch you could get a shock from the push button itself. Use wire

cutters to snip off any such stragglers, and use

this technique to

make a good solder connection in tight places.

Make sure that all cords entering

the box have some kind of strain relief. I will explain... The term Strain

Relief is, in this sense taken to mean, the point where the wire makes entry

to the box, the wire is securely fastened to the box such that a good hard

yank on the cord cannot disturb the wiring inside. One way to accomplish this

is to, prior to wiring the box up, drill a hole through the box, where you

want the cable to enter the box, the hole should be no bigger than necessary

to accommodate the wire with heated shrink tubing covering it. Next slide the

wire into the hole, and from the inside of the box grab hold of the wire, and

pull several feet of it through the hole. Now select a piece of shrink tubing

that is about 4 inches long, and no larger than needed to fit around the cord.

Slide it back about nine inches from the bare end of the cord. Now tie a knot

in the cord, shrink tubing, combination such that the knot is centered so

that there is a half inch of tubing extending from the knot toward the bare

end of the cord, and the remainder of the tubing, probably two inches or so

is extending toward the box, and plug end. Tighten the knot. Now heat the

tubing with a butane lighter, with a smooth waving motion as you rotate the

cord back and forth to distribute the heat of the flame evenly, so as not

to scorch the shrink tubing, or the electrical cord. This will shrink the

tubing down around the knot, and the cable, and when it cools it will be

somewhat stiffer. Next pull the cable back into the box so that the knot

rests against the inside wall of the plastic project box. Now use a Hot Glue

Gun to anchor the knot securely to the plastic project box inside wall.

Note: Rubber cement will work also but I caution you not to use Silicon

Rubber glue, because it gives off Ascetic Acid vapors, long after the project

is completed. These vapors over time will penetrate the enclosure of the

switch and corrode the electrical contacts inside, rendering the switch

useless, and perhaps dangerous.

After the glue sets up, on the knots of both cables, and the box is wired and

inspected, place the lid on the box, and screw in the corner screws. Now you

are ready to perform a continuity test. Connect both clipleads together, and

and clip them to one of the prongs of the plug, and use a separate clip lead

to clip both ends of the plug prongs together, and clip the common wire of

your Multimeter to the same mass of interconnected plug prongs, and clip

leads. Set the meter to the highest Ohm scale possible, probably Rx10000, and

momentarily test the meter by touching the other meter probe to a different

point on mass of interconnected plug prongs, and clip leads, just to see that

the setup is working. Now touch that meter probe to every metal object on the

box, one object at a time, watching the meter, for any sign of conductivity.

Do this once with the button released, and once with it held down. You are

testing for any unforeseen electrical path to the surface of the box.

Next unhook every thing, now connect one clip lead across the two prongs of

the plug, and both clips exiting the Suicide Cord to each other, place one

meter lead on the Suicide Cord's plug end, and one on the joined clips.

This should show an open circuit while the pushbutton is released, and

a closed circuit when it is pressed.

Next disconnect the meter leads from the Suicide Cord, now separate the clip

leads exiting the Suicide Cord from each other, and connect one each to the

two meter leads, leaving the lone clip lead that is joining the prongs of the

plug together, connected. Once again the meter should see an open circuit

when the button is released, and closure when it is pressed. If these checks

are good, as a last test set the Multimeter to the lowest resistance range

probably Rx1, touch the probes together, to allow you to zero the meter, and

then open them. Now pressing the button should read no more than a tiny

fraction of an Ohm. If all these tests pass your box is ready for the final

live test.

Live Test:

Get a working table lamp, plug it in, switch it on to insure it lights.

Unplug it while it is working, and clip the two clip leads of the Suicide

Cord to the prongs of the lamp's plug. Now observing all of the safety

rules, and with an informed onlooker present, plug the Suicide Cord into

the extension cord hanging from the table leg, nothing should happen, if

anything happens pull the Suicide Cord's plug out immediately.

Let me elaborate:

As you plug it in be anticipating nothing, psych yourself to reflexively

pull the plug out, as an automatic response to any kind of reaction, if

the toilet flushes in the next room, just as you plug it in, and you

reflexively yanked the plug out, because you heard something, after you

calm down, you can always do the experiment again, once you've determined

that the toilet had nothing to do with your experiment.

If this phase of the test went Ok, press the push button, both the lamp,

and the Neon warning lamp in the Suicide Cord's control box should light

when you do this. Release the push button, and reach up and turn off the

switch on the lamp, the Neon warning lamp should remain out, and it, and only

it, should light when you press the button this time. Now for the final test

press the button to insure that only the Neon warning lamp, lights as you push

the button, and extinguishes when you release it, the table lamp should

ofcourse remain out during this phase of the test. Now pull the plug of

the Suicide Cord out of the extension cord's receptacle. If this phase of

the test went Ok you now have a tested Suicide Cord, use it with care.

What the final phase of the test is doing, deserves some explanation. Earlier

tests determined that the push button switch when closed, could indeed deliver

enough current to the clip leads to operate a substantial load, in this case

the table lamp. The final phase of the test insures that with no load applied

the Neon stays out, the reason for pressing the button, is to insure that

the table lamp is indeed switched off, some table lamp switches, are designed

for three way bulbs, and if you had one of these, and someone unbeknown to

you, had inserted a regular light bulb, you may think you turned it off,

without actually doing so. Pressing the button, the last time, expecting only

the Neon to light, will alert you to this, allowing you to get this final

phase of the test right. The purpose of this final phase, is to test your

control box, especially the switch, for leakage current. If leakage current

is low enough to prevent a Neon Glow Tube from lighting, it is below the

level that is dangerous to people.

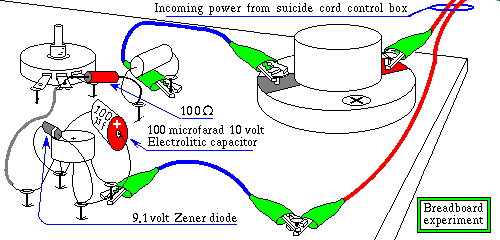

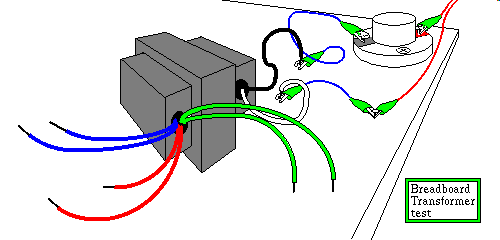

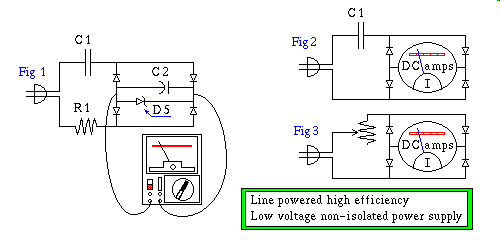

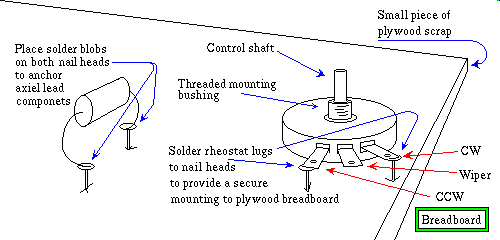

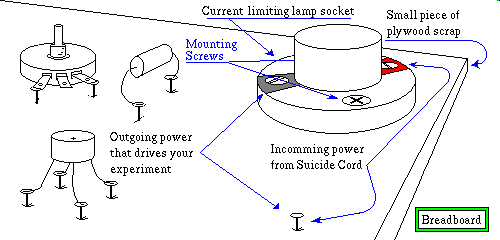

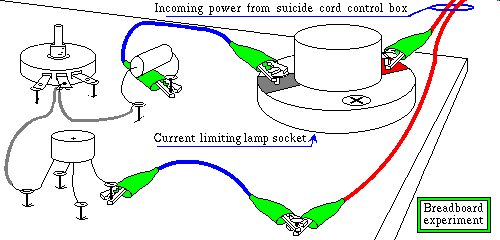

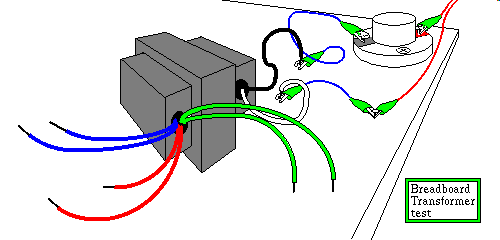

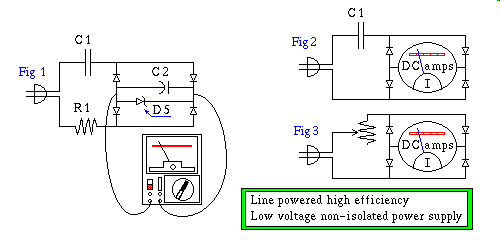

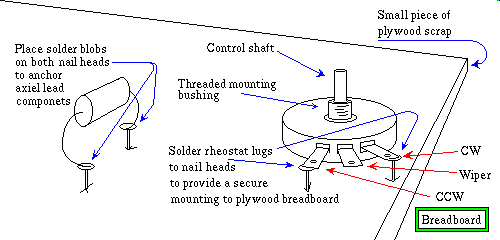

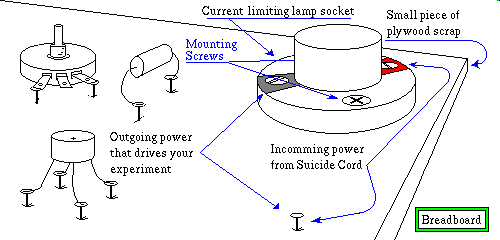

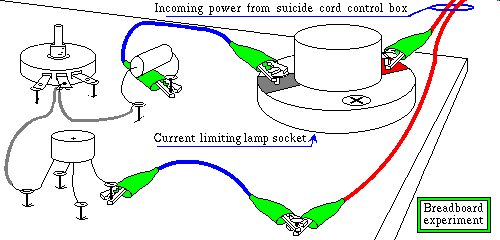

Now you are ready to setup your breadboard. I will assume you have read

through this entire page, and acquired the necessary components to build it.

I show below a breadboard partially wired up for the first phase of the

experiment. This is not intended to show you how to wire it up, that's

what the diagram is for, rather this is to show in a general way how to

make connections to nail heads, and device terminals, and the like.

Start the download of the audio discussion, now while looking this

experiment over, and when it starts playing place the drawing for the

"Breadboard experiment" in the center of your browser's screen.

014_HV_bred_bord.mp3 Audio discussion

of high voltage breadboarding 8.41 meg

http://www.leviton.com/sections/prodinfo/lamphold/laframe2.htm#cats

Porcelain and Phenolic Lampholders

Pony Cleat Type Dimensions in inches

DESCRIPTION CAT # RATING OD OH C

Candelabra Base Plastic 10028 75W 125V 1 7/16 7/8 11/8

Miniature Base, Plastic 10020 75W 125V 1 5/16 7/8 31/32

Medium Base, Phenolic 9063 660W 250V 1 7/8 1 1/2 1 5/16

Medium Base, Porcelain 19062 660W 250V 1 7/8 1 1/2 1 5/16

Leviton 9063

A word about using a light bulb as a current limiter. If you measure a 100

watt light bulb with an ohm meter, you read about ten ohms, and if the bulb

were to stay at ten ohms, when plugged in, it would draw 1440 watts! Cold

filament resistance is much less than when it is hot, which makes it much

more like a wire when it is cold, but still is useful as a current limiting

device. I re-iterate this here, because I have some very

interesting formulas that

allow you to calculate things like the actual bulb life you will get

if you operate the bulb on less than it's design voltage, or what

resistance its filament will provide at differing voltages, and so forth.

-------------------------------------------

Components needed for this experiment:

An inclosed internal cabinet wiring type

120V light socket, eg. it should look

like the one in the illustration above

Leviton Corp. Catalog number 9063

100 watt 120 volt light bulb

A 2 or 3 amp fuse that fits in light socket

C1 - 1.0 microfarad 250 volt capacitor

1.5 microfarad 600 v will also work

R1 - 3000 ohm 3 watt potentiometer

3500 ohm 5 w will also work

1.0 amp 200 volt Diode bridge

4.0 amp at 600 v will also work

Ancillary materials:

Wood screws for fastening the light socket

20, approx 1 inch long, flat head nails

10" by 15" by 1" thick piece of plywood

Some hookup wire

Some Alligator Clip Leads

One assembled and tested Suicide Cord

A good reliable VOM (multimeter)

A sturdy worktable with an insulated top

A heavy duty extension cord

-------------------------------------------

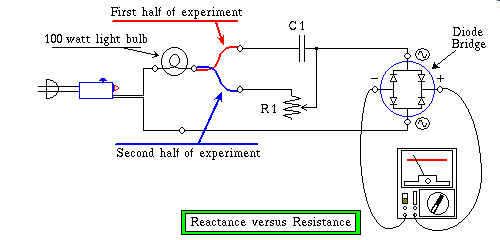

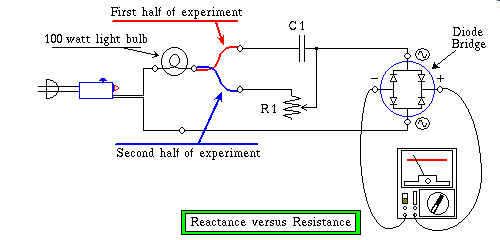

Ok so wire it up, and use the red link wire, shown in the Resistance versus

Reactance diagram connecting the light bulb to the capacitor, omitting the link

wire shown in blue, that one is for the second half of the experiment. The

red, and blue links are, in reality, most likely, going to use the same

alligator clip lead, in both halves of the experiment, the only difference

being that in one, the clip is connected to the capacitor, and in the second

half it is connected to the potentiometer.

It is standard industry jargon to refer to capacitors as caps, and

potentiometers as pots. I will at some point dispense with the long form, and

so I air this now to avoid confusion later.

Now look at your breadboard, and imagine what you would do when you unclip

the alligator clip from the capacitor, and connect it to the potentiometer.

There are three terminals on the potentiometer, this experiment uses only two

of them, the choice you make of which of the two remaining terminals to use

determines whither clockwise, or counterclockwise rotation of the pots control

shaft causes the resistance of the pot to increase or decrease. Put in other

words, if you connect say the middle terminal, and the left terminal to the

ohm meter and start turning the knob for maximum resistance, if you then were

to connect the meter to the middle and right terminal you would see nearly

zero ohms. As a critical step in the preparation of this experiment you

need to mark, read this get out your sharpie, or magic marker, and some how

draw arrows near the pot, pointing to the terminal you intend to connect the

clip lead to, when the second half of the experiment is performed, and draw

an arrow that indicates which direction the knob needs to be rotated to

achieve maximum resistance for your chosen clip lead connection. As the final

step dial it to maximum resistance, and be sure you know that you are reading

the resistance scale, they are usually ordered in the reverse of all the

other scales. If you get this wrong, you will likely burn out your meter,

later when you go to do the second phase of this experiment.

A word of caution:

If you have selected the Range Doubled 43 Range Multitester that Radio Shack

puts on sale from time to time, I mention this one because I have information

on it, the zero ohm current at the probes of the meter, when set to Rx1000

is 0.125 ma, and at

Rx100 = 1.25 ma and at

Rx10 = 12.5 ma and at

Rx1 = it's a whopping one eighth of an amp!

I'm about to show you an extreme however very common example, of how

destructive a simple ohm meter can be to components you might want to measure.

Let's say you have a one megohm, half watt pot, and you dial it all they way

down to as low a resistance as you can get, you'd be lucky to get it down to

50 ohms, ok so 50 it is. The formula for power is P=(I^2)*R if you know the

full scale zero ohm current, you can read the current directly off the dial

of the multimeter, by reading a scale of that range. In this instance 50 ohms,

at a scale setting of Rx1 draws 20 ma, and 0.020 squared is 0.0004 times 50

ohm is 0.02 or 20 milliwatt. That doesn't sound like much, but just wait till

you see what it's going into. The one megohm half watt pot, is dialed down to

50 ohm, thus only fifty millionths of the carbon resistance element is

available for dissipation of power. Since the whole pot is a half watt pot,

the active area of the resistance element is only capable of 25 microwatt,

and the power the ohm meter is applying to the poor defenseless little pot,

is nearly a thousand times greater! Can you say poof. In truth it would take

Hollywood Pyrotechnics to produce anything visible, however this does indeed

damage the pot. The damage manifests itself as erratic operation near the

damaged end, as the wiper arm makes intermittent contact with that area of

the resistance material that has been scorched.

A little common sense here is required, measure the far two terminals of the

pot if you don't already know how many ohms it is Stop to Stop.

Then if you want to measure the wiper arm through the resistance element to

the end terminal, with your handy VOM, if while measuring the resistance

of a pot, as high as 2.5 megohms, should you have this uncontrollable urge to

dial it down to zero, use the Rx100 scale. I give you a table of ohmmeter

range settings that should not be too destructive for the short duration of

time it takes to make a reading. These guide lines at their extremes, stress

the pot at a rate four times the pot's wattage rating, but all the heat is

concentrated in such a small area, that it will most likely dissipate

without doing any noticeable permanent damage. Remember the Range Setting

shown is the lowest range setting that you should be using for a pot

with less than or equal to a full Stop to Stop resistance, shown

in the chart, and of a given wattage greater than or equal that shown in the

chart.

-------------------------------------------

1 Watt Pots 1/4 Watt Pots Range setting

ridiculous 250 meg Rx1000

10 meg 2.5 meg Rx100

100 k 25 k Rx10

1 k 250 ohm Rx1

-------------------------------------------

These guide lines are loosely based on the aforementioned meter, loosely in

that, I try to take into account that the small size of the energy dissipating

region of the resistance element, will more readily carry heat off from the

affected area. Additionally the fact that maximum power transfer occurs at

fifty percent of the Thevinized voltage, or if you prefer Nortonized current

of the ohm meter's output. Thus the meter is at half scale when maximum power

transfer occurs, and on these meters, this point on the dial is ten on the

ohms scale, thus 10 ohms draws 62.5 ma on Rx1 dissipating 39 mw, 100 ohms

draws 6.25 ma on Rx10 dissipating 3.9 mw, and soforth, here's a table.

-------------------------------------------

Range Resistance Power

Rx1 10 ohm 39 milliwatt

Rx10 100 ohm 3.9 milliwatt

Rx100 1000 ohm 390 microwatt

Rx1000 10000 ohm 39 microwatt

-------------------------------------------

Electrical Safety note:

Use the same kind of procedure you used for checking metal surfaces of the

of the Suicide Cord's Control box, to check to make sure that any metal

surfaces you need to touch are not electrically connected to any of the

wiring. Especially the control shaft of the pot, because you need to turn

this while power is applied, in the second half of the experiment. Also

test the metal body parts, and if they show conductivity, make a mental

not to touch them while the circuit is powered up. Just as important is to

know what portions are insulated, because part of what you will be doing

is feeling it for signs of heat, eg. increase in temperature of about 20

Fahrenheit degrees, and you should know what is safe to touch, before you

get to that stage.

Contemplating the cosmic one-ness of the above experiment.

Ramifications:

As the experiment clearly demonstrates, a pure reactance does not dissipate,

or use energy, so you might wonder since it is drawing current, but not

power, can I draw current without spinning my electric meter. The surprising

answer to this question is yes! Electric meters are designed to measure true

power, and since a reactive load does not dissipate, or use power, they don't

register on an electric meter. That said, nothing is free, there is a price

for all of this, current is being drawn after all. So who pays? The electric

power utility, that's who. The additional current that your little reactive

load presented to the AC powerline, resulted in additional current flowing

through the transmission lines that ferry the power to your house. That

additional current passing through copper wires, that have resistance,

is converted to heat, and does require power.

The irony is not lost on Electric Utilities, they offer discount incentive

programs to major industrial users of electricity, in exchange for their

cooperation in maintaining balanced power factor loading on the powerlines.

It doesn't stop there, in Europe, and some other parts of the world, and

someday soon even in the US, laws are being passed that require balanced

power factor loading on any household appliance sold, above a certain wattage

rating. The wattage rating varies, from country to country, and is reduced

over time as technology improves the cost/benefit ratio, currently my

understanding is that some European markets require this on 50 watts or more,

but don't quote me on this, if you intend to design an apparatus for such a

market, check their laws, and get information on regulations still in

committee before finalizing your design, because by the time you gear up for

production you will probably be required to comply with laws, that at the

time you asked, were only a gleam in a law makers eye.

None of these laws apply to a one of a kind prototype apparatus, such a law

would stifle innovation, and be utterly unenforceable, many governing bodies

have tried to pass such laws in the past, and most have learned by experience

that unless a law has the backing of the large majority of the people, and is

technically capable of producing the desired result, it is ultimately

repealed, and all the expense trying to force the impossible to work, is

thrown away, a total loss. Law makers are believe it or not, even in

dictatorships, sensitive to these realities, they in some cases in a face

saving move, such as the failed " ", turn

a blind eye to these realities until such time that there is a consensus for

change. I am a guarded optimist, in the future we can hope these governing

bodies will take seriously the information that science provides, without

paying science to cook the results. Even middle managers can screw things up

though, Space Shuttle Challenger, and the Hubble Telescope were avoidable,

if only the middle managers would have listened. You have a duty to make

them understand, if you ever find yourself in such a position, exercise it,

because you can't undo tomorrow what you fail to correct today, and it will

haunt you for the rest of your life.

", turn

a blind eye to these realities until such time that there is a consensus for

change. I am a guarded optimist, in the future we can hope these governing

bodies will take seriously the information that science provides, without

paying science to cook the results. Even middle managers can screw things up

though, Space Shuttle Challenger, and the Hubble Telescope were avoidable,

if only the middle managers would have listened. You have a duty to make

them understand, if you ever find yourself in such a position, exercise it,

because you can't undo tomorrow what you fail to correct today, and it will

haunt you for the rest of your life.

I actually performed this experiment with two capacitors that I had on hand

with suitably high voltage, a 1.0 uf, and a 3.3 uf, both at 250 wvdc

(working volts direct current) and I used the measured current to calculate

the actual capacitance of them. Here is the results of that experiment.

Oh and one other little detail, a non-polarized cap that is rated xx volts

DC doesn't mean that you can't put AC across it, it just means that you

have to consider the "peak" voltage of the AC you are applying to the cap,

specifically if it is a sine wave, multiply the RMS AC voltage by 1.414 as

you learned in lesson 010, the lesson on Sine Waves.

-------------------------------------------

I measured 48 ma with the 1.0 uf

120 / .048 = 2500 ohm Xc

1 / 2 Pi 2500 60 = 1.06 uf

140 ma with 3.3 uf

120 / .140 = 857 ohm Xc

1 / 2 Pi 857 60 = 3.09 uf

-------------------------------------------

014_HV_bred_bord_4.mp3 Audio discussion

of high voltage breadboarding 4.07 meg

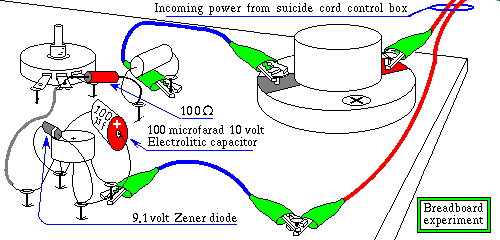

You may be wondering what the pot is doing in this circuit, the profound

answer to that question is nothing. But you say, it is shown soldered to

a wire and the 100 ohm resistor. Ok, not nothing, the pot's middle wire

is simply serving as a securely anchored terminal, but the pot itself is

not really part of the circuit, it's just a handy anchor point, oh and by

the way, don't forget to remove the grey wire that was there before the

resistor was installed in it's place, in other words, snip out the grey

wire that previously was connecting the 1.0 uf cap, and the wiper arm of

the pot.

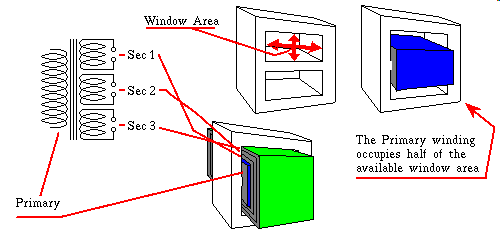

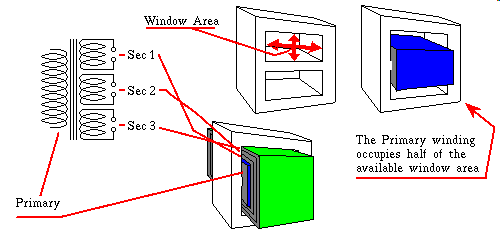

Identifying windings of an unknown transformer

This subject is one of those things that when the pieces all fall into place

everything makes sense, and prior to doing that it appears to be a black art.

To really understand how to properly categorize an unknown transformer, you

need to think like the guy that designed it, and to do that requires a

rudimentary understanding of what tradeoffs are considered in such a design.

So bear with me, this will get a little strange. If you apply a small AC

voltage to one of the windings of a transformer, all of the other windings

will present at their various turns ratios, voltages that are ratiometric to

the input voltage you have applied to that one winding you are temporarily

using for a primary winding. Remember there really is no such thing as a

primary, and secondary winding, in a transformer in any absolute sense,

rather the geometry, or if you prefer the "bobbin window area" is divided up

to optimize for maximum power transfer, and using a secondary winding, as

a primary, has little effect on the transformers over all effectiveness,

unless it has a multiple secondary windings. Why? The designer of a multiple

winding transformer must set aside half of the available window area for

putting power into the transformer, the remainder if it is a simple two

winding transformer, will be a winding that is used to pull power out of

the transformer, a two winding transformer, read that, one primary, and one

secondary will operate equally effectively in either direction. However

if it is a transformer with two or more secondaries, say three by way of

example, what you have is three secondaries sharing the other half of the

available window area

In truth careful transformer design tries to take into consideration the

fact that layers of insulation use up window area, this is especially true

of multi winding transformers. So much so that a transformer with ten

windings has only about half the power output of a two winding transformer

of the same size and weight. Then there is the matter of wire resistance,

since there is more wire per turn the farther out you get from the center

of the transformer's core, the more electrical resistance you have in the

copper windings the farther out you get from the center. It would be a poor

design indeed if this were overlooked. A transformer not given attention to

this detail, is likely to be very lopsided, for instance, an isolation

transformer, if designed properly should have equal DC coil resistance

on both primary, and secondary. In fact if designed right, you should not be

able to distinguish between the primary, and secondary by any DC or low

frequency measurement you could make external to the transformer. So how

would a transformer designer go about getting the resistances to match in an

isolation transformer? The answer is, you would use smaller diameter wire

on the primary, because that winding is shorter. The smaller diameter wire

has more resistance than a larger diameter, but, being shorter compensates.

Then after it is wound, the secondary is wound on top of it. The secondary

is longer, even though it has exactly the same number of turns as the

primary. The added length means more copper wire, and more resistance, but

the fact that we are compensating by using larger diameter, eg. lower

resistance per linear unit wire, with any luck the two windings resistances

match perfectly. In practice luck has nothing to do with it, there are a

series mathematical formulas that determine what wire size to use to place

the transformer in proper balance. These formulas result in primaries that

occupy considerably less than half of the available window area as a

practical matter, but as a first approximation, the notion of the primary

occupying the first half of the window is more easily understood

Transformers in the wild vary widely, from one sub species to another. If you

ever see a transformer with a primary rated 120 volts, at 60 hertz only, this

is a transformer wound to run well into the saturation curve, and it will

idle hot, compared to it's international 50/60 hertz counterpart. By idle,

I mean power is applied to the primary, without any load connected to any of

the secondaries. A transformer rated at a given voltage, for 50/60 hertz,

means that it will run on either frequency, obviously if you run it at the

lower frequency it will run right at the onset of saturation, but if you live

in a 60 hertz country you will never see 50 hertz, and if the need arises you

can get an additional 15 to 20 percent more voltage out of such a transformer,

by running at a little higher input voltage, or setting the tap to a lower

value. If you do this it will idle about as hot as it would if it were

running on European, or Japanese 50 hertz current using its normal design

voltage.

Caution:

Idle any transformer you intend to do this to, for four hours, to allow it to

reach thermal equilibrium, before you wire it up permanently. And while

waiting for it to stabilize, touch the frame of the transformer under test,

every minute for the first five minutes, then once every five minutes for

the next half hour, then once every fifteen minutes for the next hour, and

then once every hour there after until you are sure it has gotten as hot

as it's going to get. It should get no hotter than a temperature that you can

comfortably hold your finger in contact with the frame for ten seconds.

If it gets hotter than that, you're pushing it too hard, back off on the

input voltage just a little, or set the input tap up one voltage above the

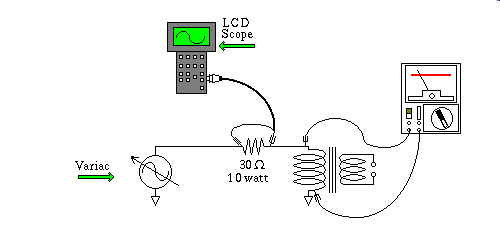

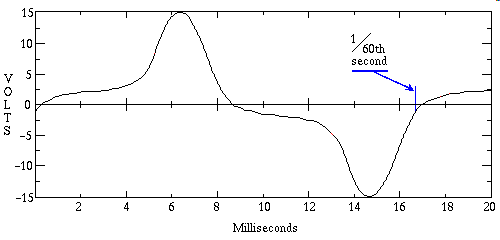

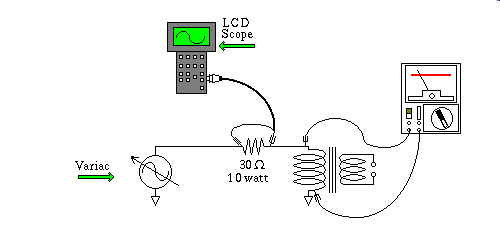

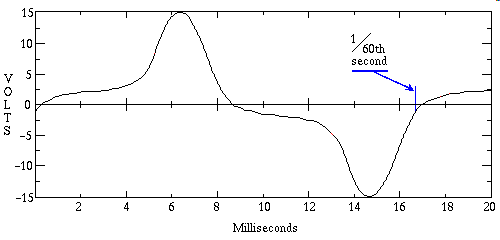

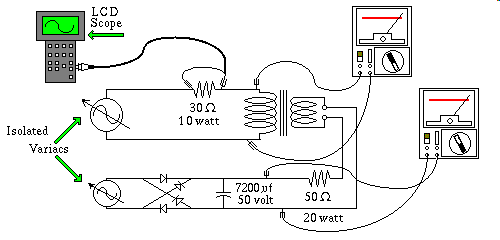

present setting. I show below a circuit to measure the current waveform of

a fairly large transformer running at the onset of saturation, followed

by the actual waveform itself.

In the above waveform the variac is adjusted such that the meter reads

120 volts and the voltage plotted in the waveform is an indication

of the current flowing through the transformers primary, in that it is

a measurement of voltage drop across a series current sensing 30 ohm shunt

resistor. Thus from one millisecond to the next the current flowing through

the coil of the transformer's primary winding is charted on the Velleman

Hand held Liquid Crystal Display Oscilloscope. The Velleman has several

advantages over conventional oscilloscopes, plus a few draw backs. The main

advantage here is that I can plug the Velleman into the serial port, set

the port to 9600 baud, and the computer can read the waveform, as a list of

points, that various Math Visualizing programs can output as a dot png file

that your web browser can properly display. Another advantage is that it is

battery powered, while the actual measurement is taking place, thus there is

no possibility of a ground loop, that poses a danger to both men/women and

especially machine. I provide more on

the Velleman K7105 Scope

should you require such info.

Notice that the waveform is anything but linear, a linear current waveform

would look sinusoidal, this one is anything but.

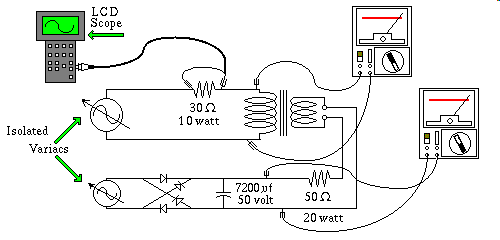

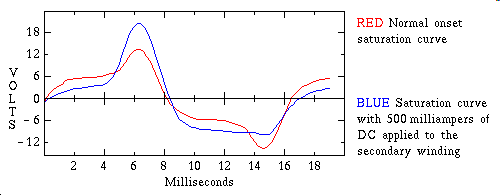

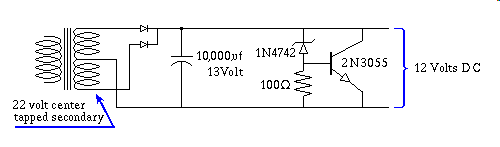

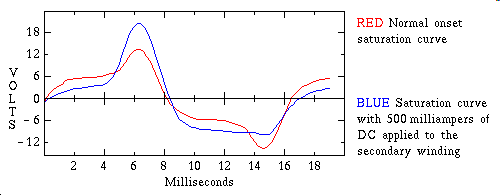

The next circuit is a variation on this one, I setup a DC power source that

can pump an average of 500 ma. into a 25 volt RMS secondary. The DC power

is composed of a smaller, I.E. lower voltage variac, that provides a

controllable AC voltage to a diode bridge, capacitor combination. The

capacitor is suitably large, such that it's impedance, or RC time constant

with respect to the resistor, is negligible. For our purposes it behaves like

a variable battery. The current from the variable battery is limited by

the series 50 ohm resistor, and I show the saturation waveforms for both,

where in case one, the variable battery is set to zero volts, but

still connected to the secondary through the 50 ohm resistor. And case

number two, where I actually pump the transformer's secondary with an average

of 500 ma. The result is a non-symmetrical saturation curve, shown in

blue superimposed over case one the reference wave shone in red. The

reason the DC powersupply and current limiting resistor remain connected

during the reference phase of the test, is to establish the primary current

waveform while the secondary winding is being loaded by the 50 ohm

resistor, failing to do this would introduce additional variables into the

experiment, when we went to the phase two, where we actually pump the

secondary winding with polarizing direct current.

Not to spend a lot of time on this, but earlier I mentioned the curiosity

of Polarized Inductors this experiment demonstrates the phenomenon,

by placing a direct current on one of the windings of a transformer, that

is otherwise being used as an inductor driven to the onset of saturation.

The direct current flowing in the secondary, replaces the permanent magnet

in the Polarized Inductor and illustrates the point that coils are

not so different from one another, in that they're behavior can be coaxed

into doing many specialized duties. A variation of this phenomenon is the

heart of a flux gate magnetometer. Oh there I've gone and done it, straying

way off the path, Ok back to identifying Wild transformers.

Ok now let's say you have a transformer of unknown origin, you can't even

be sure if it is intended to be powered off the line voltage. Well the first

thing you do is to ohm it out to see what paths of current flow between

the lead wires, or terminals of this undomesticated transformer. Draw a

diagram of the paths of electrical continuity, and write down their DC

resistances. As a final check test to make sure that there isn't a path of

conductivity you may have missed, remember often transformer windings have

many taps. If you encounter a single wire that appears not to be connected

to anything note this one with suspicion, it could be an interwinding shield

or maybe an open winding, most likely a burned out transformer. If you

encounter two such terminals, it is almost a certainty that it is a fried

transformer. If the transformer is fried, mark it as bad, and go on to the

next one.

Using an AC wall wart that produces six volts AC, power one of the medium

resistance windings of the undomesticated transformer. Measure the six volt

AC with and without the load of the undomesticated transformer's winding

loading the wall wart. If it droops below four volts AC, try another winding

of the undomesticated transformer. Now with the undomesticated transformer

winding connected to the six volt AC source carefully measure the other

windings of the undomesticated transformer, and write their respective

voltages down on your diagram. Do this carefully, an undomesticated

transformer can do anything turns ratio wise, it could boost that six volt

input up to hundreds of volts on one of the other windings, so treat them as

dangerous, until you have measured them, and know that they are not.

One way to gain experience with this phase of the procedure is to carry out

this procedure on a transformer that you really do in fact have data on, as

a dry run. Doing a dry run, is also useful at several other phases of this

procedure, that I have not discussed yet, so remember this if you have any

doubt about how to carry out one of the other phases of this procedure.

When you figure out the voltages of all of the other windings, with respect

to the one winding you are pumping with six volts AC, what you have is a

crude map of the turns ratios. If you have reason to believe this transformer

was a multi winding step down transformer, there will be one winding that

appears to have the highest AC voltage, when compared to all the others, and

it is likely that, that winding is the power input winding. If that windings

lead wires exit the transformer from the opposite side of the transformer,

from all the other wires, the likelihood is even higher. If the lead wires

are color coded, and the wires you suspect from your measurements are the

power mains, eg the primary winding of a line power transformer, and

those suspected wires are either black, or white, or some

striped combination of black, and white then it is a near certainty,

that you have located the power mains, of what is a line power transformer.

On the other hand, if this transformer is known to have been removed from

Vacuum Tube equipment, including Tube based Laser, high power Microwave,

such as Cavity Magnetron drivers, Neon Sign transformers, old Oscilloscopes,

that don't use a modern solid state flyback design, etc. the highest voltage

winding will likely NOT be the power input mains. For this reason it

is important if you are about to salvage a transformer from a piece of

equipment, to note which wires were connected to the powerline, before you go

cutting wires, and since the output voltages of the secondaries usually go

to diode bridge assemblies, whose DC output goes to a filter capacitor, it

will save you enormous effort if you note the voltages marked on those,

filter caps, and draw a little diagram of what winding they were connected

to, before you pull the transformer out. Cost containment prevents

manufacturers from placing radically higher voltage capacitors in a circuit

than are necessary, although they are often a third higher voltage, than is

actually applied, to allow for a safety margin in the event of overvoltage

operation, and voltage surges. Oh and a word of caution, especially on high

voltage equipment, if you suspect the unit has been powered up recently,

go in with an insulated handled screwdriver, and touch the blade across,

the terminals of all of the capacitors in the system, in other words short

them all out, before you get in there with your bare hands. Capacitors

can recharge on their own by a process known as Dielectric Charge Migration,

essentially a discharged cap can have regions within its dielectric that

each contain charges that neutralize each other, and if one leaks off, the

cap assumes the difference charge. While probably not terribly dangerous,

it might not be very pleasant. Also Tube based equipment is these days getting

to be rather scarce, so a transformer culled from such a piece of equipment

is a very valuable find. You won't often need high voltage, but when you do

there simply is no substitute for the good old transformer you culled from

that TV set you found in the attic last summer.

Ok we will assume you have figured out what you believe to be are the power

mains of this as yet undomesticated transformer. At this point you

can if you want play with the ratios arithmetically, to derive the actual

voltages that will be present on each of the secondaries, assuming you are

right about the selection for the power mains. In fact the ratiometric

derived secondary voltages, will not be right on the button, but they will

probably be fairly close. Ok now connect up your undomesticated

transformer, to the bread board, using the light socket as a current limiter.

You need at your ready disposal an assortment of different wattage 120 volt

light bulbs, to make these tests. The bulbs you should choose for this purpose

should be transparent if at all possible, as you will be looking for a dim

glowing filament, as opposed to a brightly lit bulb, also useful is an

adaptor socket that screws into a normal one inch light socket, and accepts

the kind of bulb that you find in standard 7 1/2 watt, and 4 watt night lights

to extend your range down to those lower currents. To be able to convey the

transformer size and their attendant 120 volt primary characteristics,

several options are available to me. I could have used weight, but that would

have required people reading this page to have on hand a scale that reads

accurately in the range of a few ounces, to ten or fifteen pounds. I could

have used volume, but transformers are irregularly shaped objects that would

make it hard for readers of this page to compute the volume of transformers.

I choose a simple, and concise standard, that is accurate enough for the

kind of thing we are trying to get across. My concise approximation amounts to

this, imagine the smallest empty box, with regular right angled sides, that

the transformer will fit inside of. You don't need the box to actually fit

your transformer into, just a picture in your mind of such a box. Now measure

the transformer as if you were going to order a custom made box, that would

fit your transformer, like the glove fits the hand. You'll need three

measurements to accomplish this. Now solve for the volume of that box. To do

this one simply multiplies all three dimensions together. I will refer to

this volume as the Transformer Package Volume, or the abbreviated form TPV.

Do not include the mounting ears, terminals, or lead wires in these

measurements, I'm trying here to find a simple uniform way, we; you, and I,

can reference the meat of the transformer. For example I have a

transformer, the coil of which is wound on an exposed plastic bobbin, that

is pretty much filled with windings. the distance measured across the bobbin

is 1.8" and the dimensions of the magnetic core laminations are 2.2" by 2.7"

so I claim this transformer has a TPV of 10.692 I show a table below in

which I list this transformer as the first case study, and in the table the

first and second column show the size of the lamp screwed into the light

socket, and the actual voltage read across the lamp, followed by my TPV

specification, the transformers VA rating as defined by a thing known as the

ten percent rule, and lastly the frequency the transformer is designed to

operate at.

-------------------------------------------

Lamp TPV VA Frequency

-------------------------------------------

25 watt 20 volt 10.7 50.4 60 hz

25 watt 16 volt 37.7 140.0 50 hz

25 watt 18 volt 37.8 ----- 50 hz

100 watt 5 volt 90.0 60 hz

-------------------------------------------

The VA rating, and the ten percent rule:

To compute the transformers VA rating, this means essentially the wattage

capacity of the transformer, using the ten percent rule, requires you to have

already ascertained which winding power is to be applied to, and what voltage

it is designed to be powered with. If you decide that this is indeed a

transformer designed to operate on 120 volts AC, unscrew the light bulb, and

replace it with one of those three ampere fuses that I mentioned earlier.

Now with it running you can make more accurate voltage measurements of the

secondary windings idling, that is not powering any load. You need to know the

voltage of each of the secondaries if they're are more than one, and you also

need to have a large Rheostat, Potentiometer, or switchable load bank, to

load the transformer down with. The reason I say large Rheostat, or

Potentiometer, etc is that these resistors will be sucking perhaps hundreds

of watts for just long enough to measure the droop in output voltage the

transformer is delivering. You adjust the load bank, so that when connected

to the transformer it loads the transformer's output voltage down to 90% of

its unloaded voltage, a droop of ten percent, hence the ten percent rule.

If you know the resistance of your load bank, and the voltage of the

secondary winding at the time the load was pulling down on it, you can use

Ohms Law to compute the current. Knowing the current, and the voltage, you

can compute VA, eg. Volts times Amperes, and for most purposes thats the same

thing as Watts. A single secondary transformer is fairly straight forward,

the fun comes when trying to categorize the VA rating of a multiple secondary

transformer. For now I will say only that is beyond the scope of this lab

explanation, and that it involves a Thevinin approach to the problem.

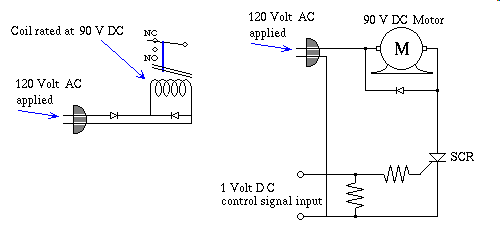

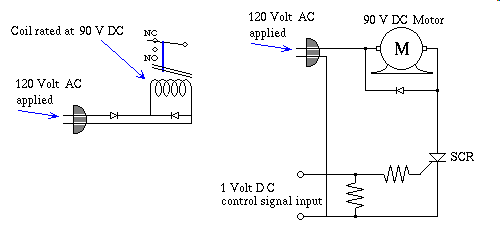

Ok I'll elaborate a little, upon finding a transformer in the wild you know

nothing about what its designer's priorities were. As an extreme example,

imagine a transformer designed as an isolation transformer with an additional

small low voltage winding intended to drive a small piece of electronics

that was to act as an Electronic Circuit Breaker a device

that pulls the lever in a relay to open the contacts of the powerful

secondary winding, thus functioning as a Circuit Breaker, with one additional

very nice feature, it has a knob to allow you to control the sensitivity

of the Circuit Breaker. Thus you can dial in any current from a few

milliamperes to the maximum the isolation secondary can withstand, maybe five

or ten amperes. Such a transformer has a very lopsided set of resource

allocations with respect to how the VA ratings of the respective secondary

windings are designed. Now contrast that to a transformer that the VA ratings

of the secondary windings more or less evenly divided up, and you start to

appreciate the complexity of this problem. Once again the ten percent rule

can be easily applied to get you a concise answer. The technique is to apply

the ten percent rule to each winding individually, while measuring the open

terminal voltage of one of the other windings, both with, and without the

load applied to the winding undergoing the ten percent rule power check.

Doing this you will likely find one winding, that sucks considerably more

power, than the others, and you will also gather a feel for the major

runner up. Now back off a little on the loading of the major winding, to allow

the runner up to perform about 80% or 90%, of its ten percent rule loading

and try combining the two loads to see if you can get a total load of both

windings to as an aggregate, load the transformer as a whole according to

the ten percent rule. Likely the other windings are so small by comparison

that bringing their loads online, won't severely overload the primary. To put

all of this in context, a transformer idling will be anywhere from 100 Deg F

to 110 Deg F depending on how deeply it is driven into saturation. When the

load is applied at the level called out by the ten percent rule, the

temperature will rise another 50 Fahrenheit degrees or so. Transformers can

tolerate at the extreme, a temperature of 180 Deg F indefinitely, however this

leaves no margin whatever for voltage fluctuations, so you never push one

this hard without providing adequate cooling. As you can see you have quite

a bit of wiggle room when assigning VA ratings of secondary windings, and

when in doubt you can always under specify, eg. err on the safe side.

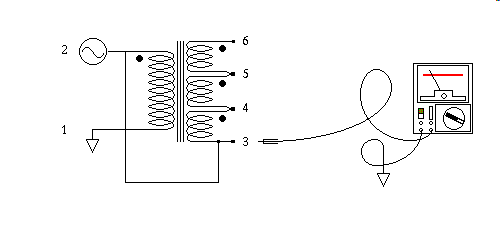

Phasing your transformer:

In the drawing below I show the example transformer wired up such that all

voltages add. I have also included phase dots on each winding,

if you connect up a transformer this way, and one of the windings seem to

subtract instead of adding to the voltage, that winding's terminals, or

wires are backwards, and if you reverse those two wires they will add voltage.

When you get done they all should add. Once this is done, you can mark them

some how, examples of marking them, are, tying a loose simple knot in the

phase doted wire, nicking the end of the wire with a pair of side cutters,

or judicious use of a modern felt tip pen.

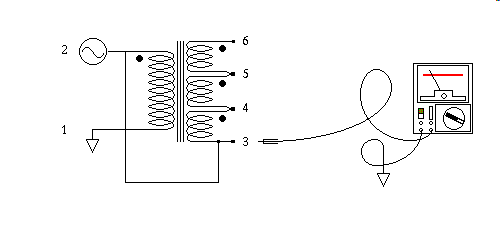

It should be obvious by now that terminals 2, and 3, are in fact the

same terminal, as configured above, I just thought I'd mention that, if this

didn't automatically occur to you, it should have, you've missed something

critical along the way, go back and review some of the early lessons.

Anyway Terminal 3 should be 120 volts with respect to ground,

your line voltage may not be exactly 120 so don't fret if it's within 10%.

Terminal 4 should be higher by the voltage of the first secondary,

terminal 5 should be higher by the voltage of the second secondary,

and finally terminal 6 should be still higher by the voltage of the

third secondary. If your transformer has one of the windings reversed you can

fix it, and go on. Once you get them all in phase, that is so that they all

add, power the whole thing down, leaving the wires of the transformer windings

connected to each other, and carry the transformer to the workarea where you

intend to mark the wires.

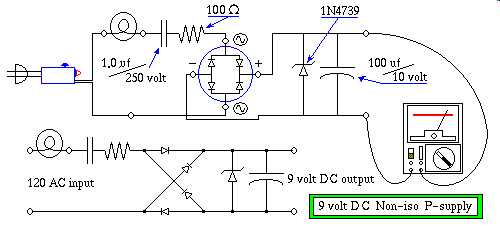

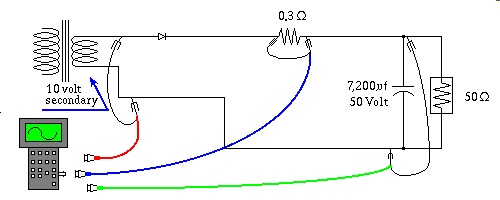

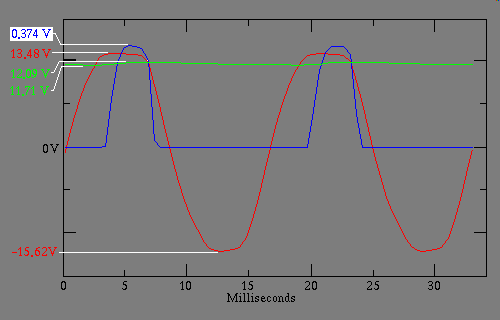

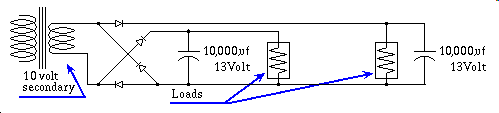

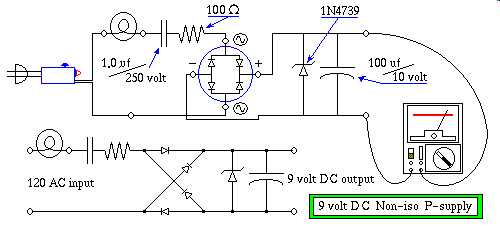

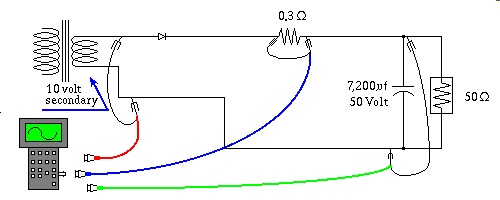

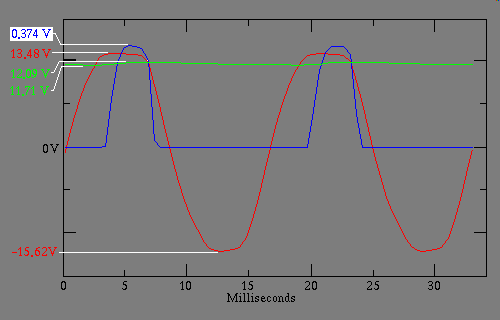

Next I show a simple Half Wave rectifier, and simple single capacitor filter

circuit, with some provision for measuring the current waveform, carried by

the diode. What is ofcourse being measured is voltage drop across the

0.3 ohm current sensing shunt resistor. The following frame I show

actual waveforms taken by the Velleman K7105 handheld oscilloscope. Notice

how, as the current waveform reaches maximum, the input voltage delivered

by the transformer, shown here in Red is severely flattened by the nonlinear

current drawn by the diode, and then on the negative half cycle, the

transformer, nolonger subjected to the diode's load, is free to produce

almost two more volts. Also observe how, as the Red positive peak forward

biases the diode, only as it exceeds the cap voltage by the diode drop,

does any energy get transferred to the cap to replenish its charge. This is

by contrast a very brief period of time, this time slice is so short, that

to accomplish the charge replenishment, almost 1 1/4 amps flow

in that brief period of time, into a cap, that is only providing

240 milliamps of current to the load. Rectifier diodes are routinely

subjected to very high repetitive pulses of current, many times the design

load current. Any series resistance, in either the cap, or the transformer

has considerable impact on the amount of power such a power supply can

deliver.

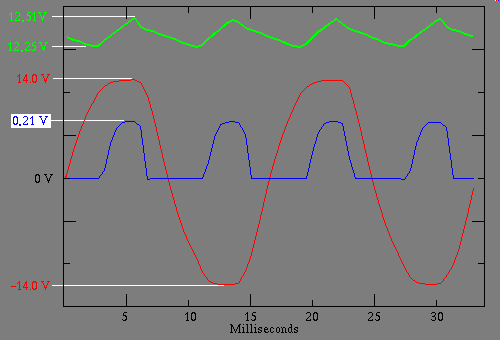

Both the Red transformer voltage waveform, and the Green capacitor voltage

waveform are measured at the same scale setting, the Blue current waveform,

is in reality a tiny voltage measured across a current shunt, and would

therefore be inappropriate to set at such an insensitive scale setting.

All of these however are referenced to the same zero reference

to make easier the interpretation of this first waveform on the part of the

student. Notice that the Green capacitor waveform has so little activity

that much of the detail is lost. In the next set of waveforms I suppress the

zero and rescale the Green capacitor waveform when I cover Full wave

rectification, because without this technique the 'Y' axis movement is

a mere single pixel. I mention this here so as to warn you not to be

complacent about zero suppression.

These are real waveforms, not textbook drawings, and some unanticipated

phenomena needs perhaps an educated guess as to the causes. First you would

expect that the capacitor voltage waveform would follow the transformer

output into the circuit by 7 tenths of a volt, but it follows by more

like a volt and a half, why? These voltage measurements were made one at a

time, and then pasted together into a composite, it is possible that the

powerline voltage fluctuated a little, or I may have absent mindedly made

the measurement with the current sense resistor still in the circuit while

I made the measurement, but even including that 0.374 volts still

fails to account for the discrepancy, so I say a combination of factors,

wire resistance of the cheap "Radio Shack" clip leads, line voltage

fluctuations between measurements, and measuring cap voltage while the

current shunt was still in circuit all came together to produce this

anomaly.

Another anomaly is the fact that the bottom half cycle, of the Red

transformer output voltage is not as round as it seems it should be

I assume this is some of the compound saturation effects of the test

setup I used, an isolation transformer drives a Variac, it drives the

transformer shown, which is exhibiting a slightly less than sinusoidal

negative half cycle.

Third I need to mention that all of these waveforms were phased, that is

aligned to each other with respect to time after the measurements were

taken, in the Grace math package, using Emacs macros to do the alignment.

I hope I got them right :-)

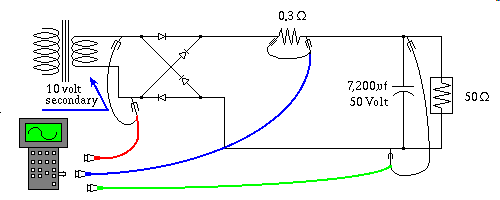

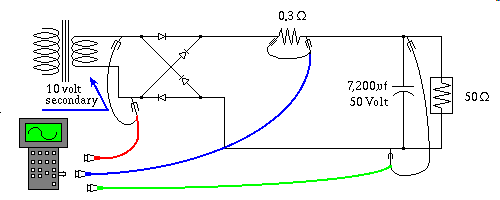

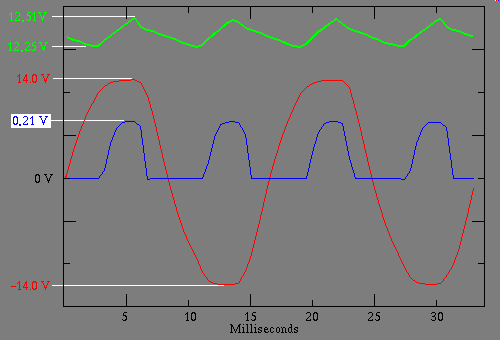

Ok on to the Full wave rectifier circuit.

Like I told you, the Green cap voltage waveform is zero suppressed

this gives me a way to provide you more detail than would otherwise be

possible. Notice that the Blue current waveform is only a little more than

half the magnitude, of its Half Wave counterpart, still delivering the same

output. This happens because it occurs twice as often, if you missed this,

study the two waveform sets, comparing them to each other. Showing the Green

current waveform in this kind of detail, allows you to see why they call

this sort of waveform a Ripple Wave, again the short rise time

that is the charge cycle, is in contrast to the relatively slow fall, or

discharge time. RC Time Constants describe the discharge portion

of the wave, and therefore the magnitude of the ripple. In normal powersupply

design you want as little ripple as possible, on the other hand an infinitely

large cap is also infinitely expensive, and infinitely heavy. not to

mention large as the universe. So you have to make some tradeoffs.

Also the smaller your ripple voltage, the more severe the exaggeration of

the diode doing all the work in an ever thiner sliver of time.

The information I've given you concerning time constants, RC discharge

characteristics, and the like is all that you really need to design such

powersupplies to a second approximation. There are formulas for many standard

configurations, you might be tempted to acquire some of them, but you

really don't need them, and few who memorize them remember them ten years on.

So I don't make a big deal about them, the Internet is vast, if you think

I should drop some pointers, drop me a line, and I'll consider it.

Analog series pass transistor based regulators present a

Constant Current load to the filter cap, and switch mode

regulators present a Constant Power load to the filter cap.

These various types of load make very little difference to the curve,

or the way you calculate the size of the cap if your ripple is small, eg.

less than ten percent. My first approximation treats the load as if it

were a constant current, and usually that's all that's necessary. Line noise,

variations in temperature, and component tolerances, all factor in to cause

far greater error than the miniscule error caused by using the wrong

current curve model. So the first approximation Rule of thumb

is to simply use the relationship of one Ampere of discharge current, flowing

out of a one Farad cap, steadily reduces its voltage by one Volt per Second.

To keep the proportions straight in your mind reducing the discharge current

slows the voltage decent, and reducing the capacitance speeds up the voltage

decent, in linear proportion.

Some texts take up weeks of your time on the above subject, and when you

try to apply all the theory in the lab you discover the fine points the

theory makes can't even be measured because of all the

noise factors. I have given you a simple practical way to

compute the size of the cap that's hard to beat. I'm not discouraging

you if you want to know the details, as I said before the Internet is a

big place, go for it.

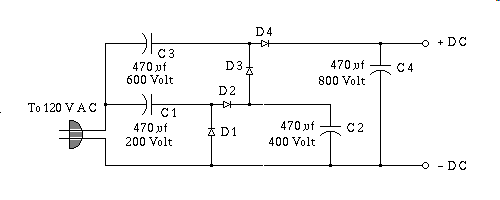

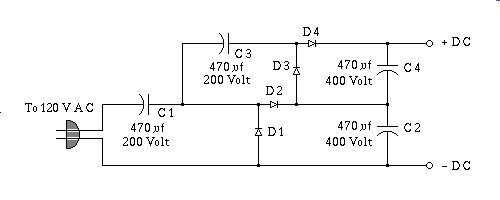

Some interesting rectifier configurations:

At this point I will assume you've tried a few of the things I've put forth

as experiments, the next section will detail some arrangements of diodes,

and capacitors, that produce useful unregulated DC power supplies.

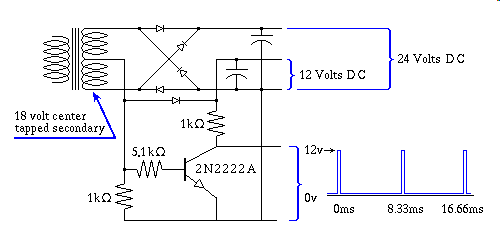

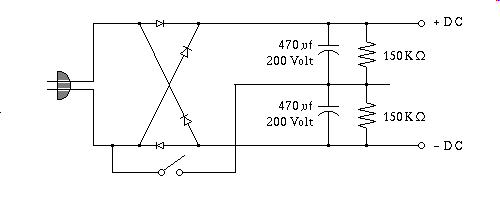

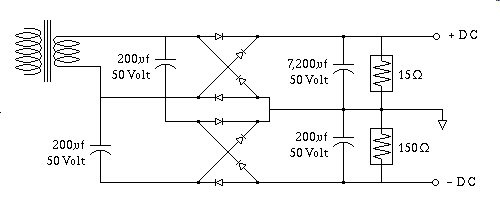

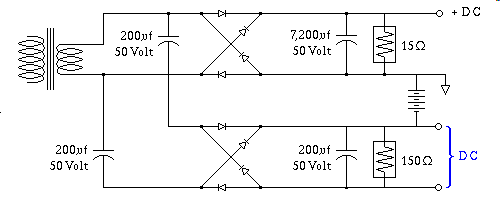

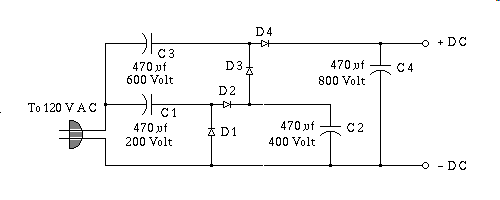

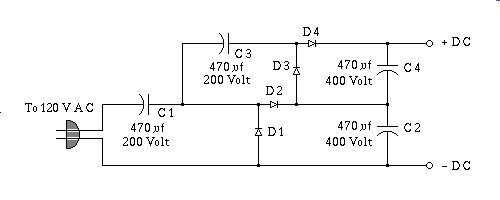

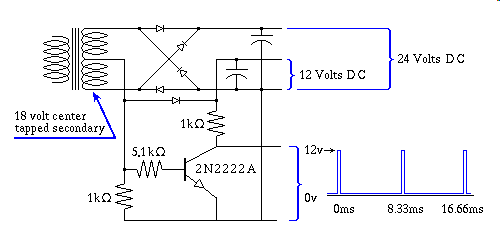

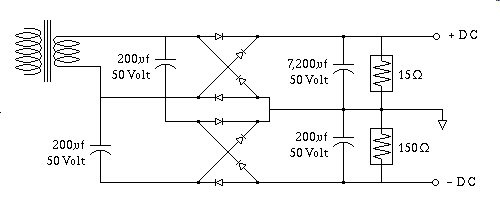

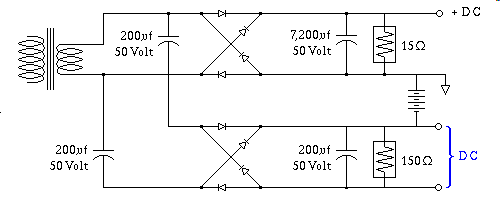

The above power supply produces two voltages from the same transformer, plus

a handy full wave signal that can be used for detecting Zero Cross. Both of

the DC voltages, are full wave rectified sine waves fed into the filter

cap and as such require considerably less filtration, eg. capacitance.

The bottom half conditions the signal into a short pulse for timing things

that rely on things that coincide with the 60 hz beat of the powerline, a

very precise timebase.

To understand how this circuit works, momentarily ignore the top two diodes